#430 FALCON FLEXO FOLDER GLUER

MACHINE CAPABILITIES

updated 12/2/15

General

- Blank width:

- Min: 9 1/16”

- Max: 35 ¼” Can go up to 36 9/16” with skip feed (½ machine speed)

- Blank length:

- Min: 29 ¾”

- Max: 95 1/16”

- Minimum panel sizes (measured score to score):

- If joint is on the large panel:

- 7 7/8” length

- 6 ½” width (exception: 4 ½” width if length + width >= than 14 9/16”)

- 3 15/16” depth (exception: 2” depth with extended glue tabs)

- If joint is on the small panel:

- 7 7/8” length

- 7 7/8 “ width

- 3 15/16” depth (exception: 2” depth with extended glue tabs)

- If joint is on the large panel:

- Maximum depth 18 ¼” (exception: 22 ½” max if width panel <= 14” for RSCs and 7 1/8” for FOLs)

- Maximum Length Panel: 37 3/8". Ask Production if over 36".

- Maximum slot: 9 5/8” (exception: 7 1/8” if depth > 22 ½”)

- Cannot run E flute. B,C, CB and AB are ok

Outside glued cartons take extra time to setup. This setup time is calculated in the estimate.

Maximum length is 47" if running flat without folding.

- Minimum panel sizes when not gluing mfg. joint.

- 7 7/8” length

- 3 ½” width

- 3 15/16” depth (exception: 2” depth with extended glue tabs)

- No minimum blank length, along as min. panel dimensions are met.

- Maximum mfg. joint width 2”

- 3/8” slots

- Hold Down Tabs – Can do, but tabs must be towards lead edge of machine.

- Die cut section:

- 36.6” cylinder.

- Maximum cutting rule straight across machine: 19 11/16”

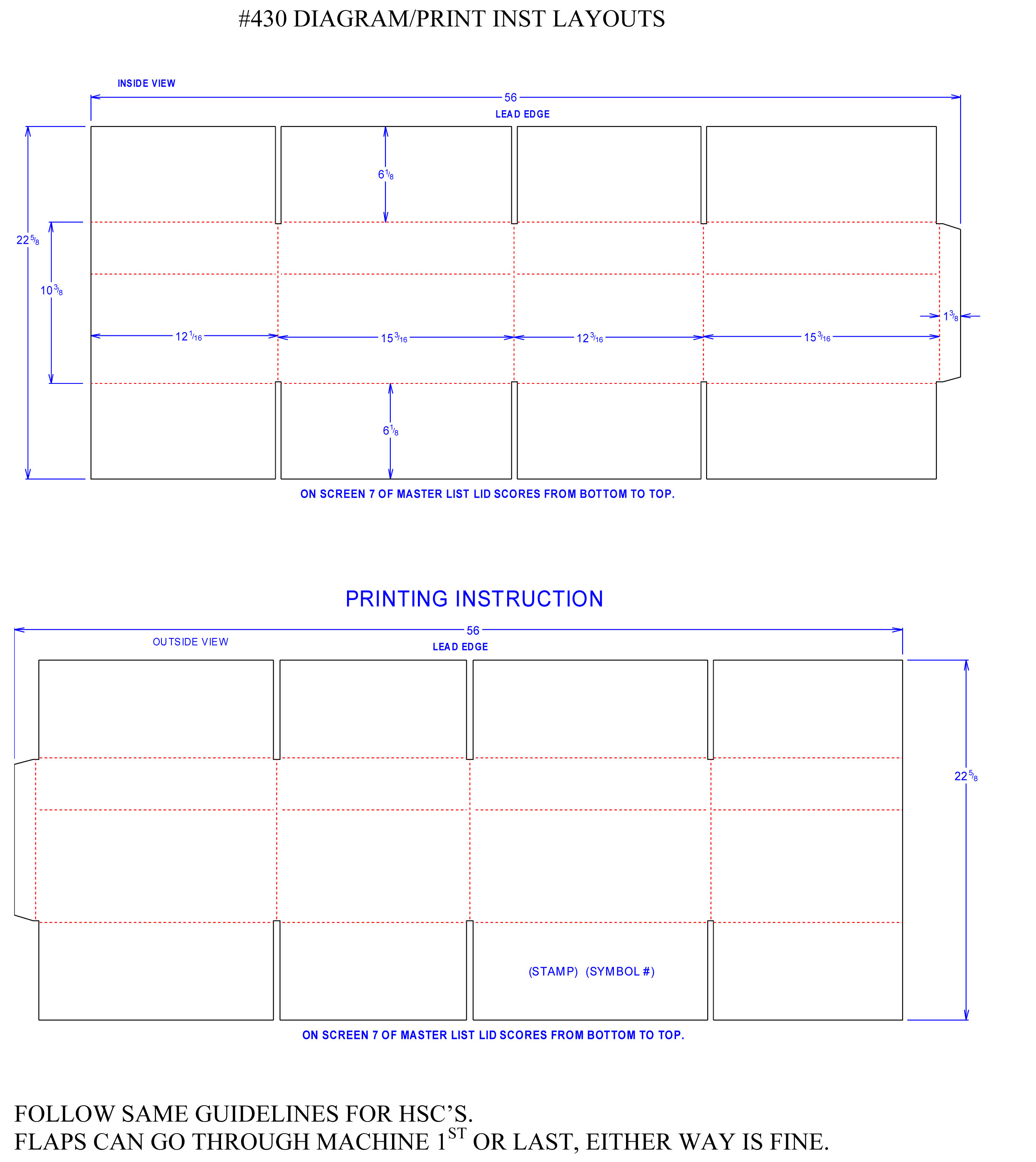

- Printing:

- 4 color

- 36.6” cylinder

- 250 line anilox rolls

- Max 45 line, 50% screen

- Print cylinder 88 ½” wide. Max print 87 ”

- Add ¼” length trim if print goes over edge of blank.

- Click here for additional printing information: Print Specifications

- Unitizing

- Unit size cannot exceed 58” in either direction

- Use 1x2 straps for Style B and C units

- Cannot run Poly Coated boxes or sheets